Medical device development is a complex and highly regulated process that demands precision, innovation, and rigorous testing. However, in an era of skyrocketing healthcare costs and increased competition, cost-effective product development for medical devices is more crucial than ever. In this article, we will explore the key aspects we see in this process in five sections: cost-effective planning, agile design and prototyping, testing and validation, efficient manufacturing, and a summary of the key takeaways.

Cost-Effective Planning

The foundation of cost-effective product development lies in comprehensive planning. To ensure a smooth and economical journey, we believe one needs to consider the following:

- Market Research: Before diving into development, conduct thorough market research to identify unmet needs and potential niches. Understanding the competitive landscape is vital to avoid wasted efforts.

- Regulatory Compliance: Engage with regulatory bodies early in the process to understand the requirements for your medical device. This will help you navigate the regulatory landscape efficiently, reducing the chances of costly delays.

- Budget Estimation: Develop a detailed budget that includes all expenses, from research and development to regulatory compliance and manufacturing. Allow for contingencies, as unforeseen expenses are common in the development process.

- Risk Assessment: Identify potential risks and develop strategies for mitigating them. A proactive approach to risk management can save significant time and money in the long run.

- Project Management: Implement effective project management tools and practices to keep your development process organized and on track. This will help you allocate resources efficiently and meet deadlines.

Agile Design and Prototyping

Efficiency in design and prototyping is crucial to reduce development costs:

- Iterative Design: Adopt an iterative approach to design, allowing for adjustments based on feedback and testing. This can prevent costly design overhauls later in the process.

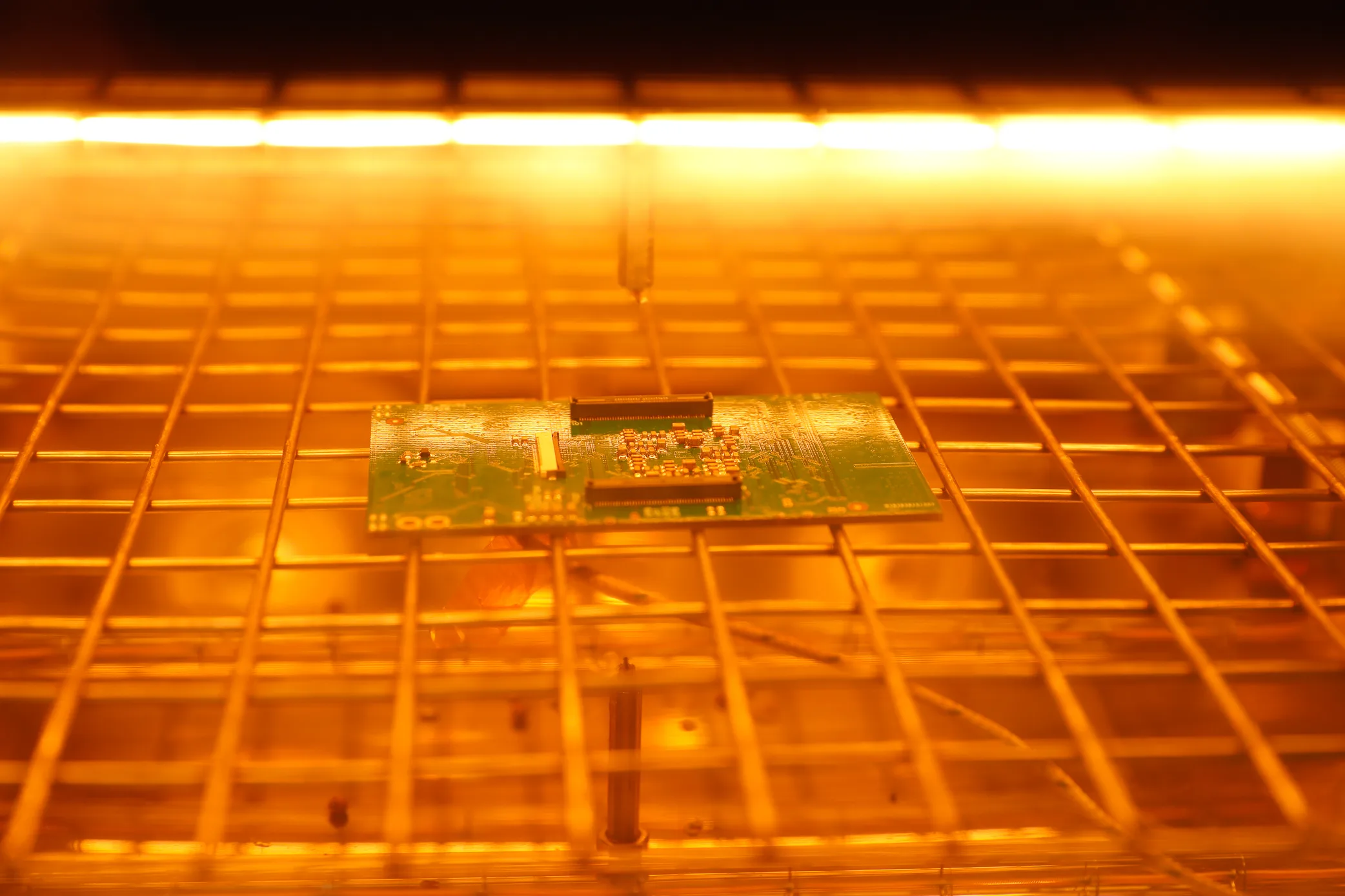

- 3D Printing: Utilize 3D printing for rapid prototyping. It allows you to test and validate designs quickly, reducing time and cost compared to traditional manufacturing methods.

- Cross-Functional Teams: Collaboration among diverse teams, including engineers, clinicians, and designers, can provide multiple perspectives and improve the quality of your product.

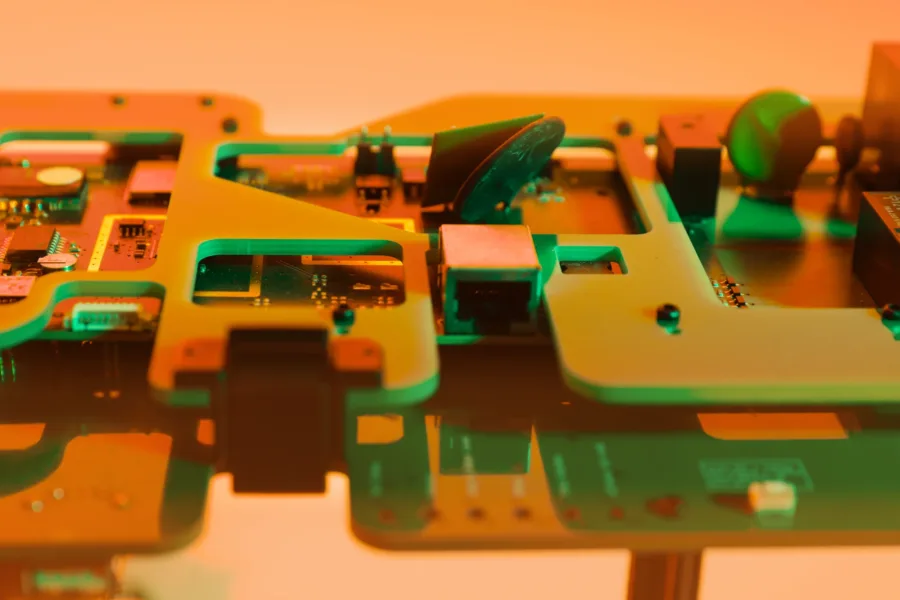

- Simulation and Modeling: Employ computer-aided design and simulation tools to optimize your device’s design before physical prototyping. This helps identify and resolve issues early in the development process.

- User-Centered Design: Prioritize user experience and design your device with the end user in mind. A device that meets user needs is less likely to require costly post-launch modifications.

Testing and Validation

We believe thorough testing and validation are essential for product quality and cost control:

- Early Testing: Start testing as early as possible in the development process. Identifying issues at this stage reduces the likelihood of costly late-stage modifications.

- Compliance Testing: Ensure your medical device meets regulatory and safety standards. Address non-compliance issues promptly to avoid delays and additional expenses.

- User Feedback: Gather feedback from potential users and integrate it into the design. This not only improves the device but also reduces the likelihood of costly post-launch modifications.

- Validation Plans: Develop comprehensive validation plans to confirm that your device functions as intended, is safe, and meets quality standards. Detailed documentation is crucial for regulatory submissions and audits.

- Documentation: Maintain detailed records of all testing and validation activities. These records are essential for regulatory compliance and ensuring the device’s safety and effectiveness.

Efficient Manufacturing

Efficiency in the manufacturing process is another key factor in cost-effective product development:

- Design for Manufacturability: Consider manufacturing processes during the design phase to minimize complexities and reduce production costs. Simplicity in design can often translate into cost savings in production.

- Supplier Collaboration: Establish strong relationships with suppliers and manufacturers to negotiate favorable terms and ensure a smooth production process. Efficient supply chains can significantly reduce costs.

- Quality Control: Implement stringent quality control measures to minimize defects and reduce the cost of rework or recalls.

- Lean Manufacturing: Apply lean principles to eliminate waste in the production process, optimizing resource utilization and reducing production costs.

- Scalability: Plan for scalability in production, so you can adjust production volumes efficiently to meet market demands without major disruptions.

Summary

In conclusion, cost-effective product development for medical devices involves meticulous planning, agile design and prototyping, rigorous testing and validation, and efficient manufacturing processes. We can help you across each of the key stages, with our world-class engineering team. By following these strategies, we can help you reduce development costs, improve product quality, and bring innovative medical devices to market faster in a cost-effective manner. This approach not only benefits your bottom line but also ensures the delivery of safe and effective medical solutions, ultimately enhancing patient care and well-being while keeping healthcare costs in check. Balancing innovation and cost-effectiveness is the key to success in the ever-evolving field of medical device development.

Accelerate your product development journey and partner with us to bring your innovative ideas to life.

Contact Turkka Laakkio Partner Dream Devices for more information.