In the dynamic world of medical device development, the journey from concept to market-ready product is complex and demanding. Medical innovation requires a partner that can offer comprehensive support at every stage of the process. In this article, we will outline our end-to-end medical device product development and engineering services, and explain the advantages this offers our partners in the healthcare and medical device industry.

Support Across All Stages of Hardware and Software Development

Our support covers all phases of development, ensuring a seamless transition from concept to market. These services include concept development, design, prototyping, testing, and manufacturing. We believe that an all-inclusive approach minimizes coordination challenges and accelerates the development timeline, from the original idea to a market ready product

Co-Creation as the Basis for Design and Product Development

Successful medical device development requires a collaborative partnership. Co-creation involves CAD modeling, material selection, and rapid prototyping, allowing close collaboration between engineers, designers, and clients. Our approach guarantees that the end product aligns with the original vision and user needs.

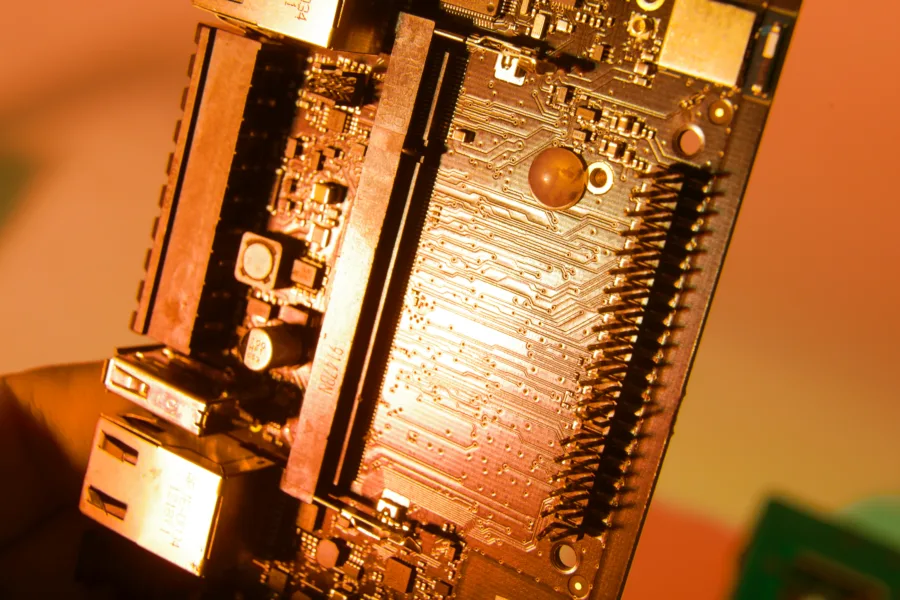

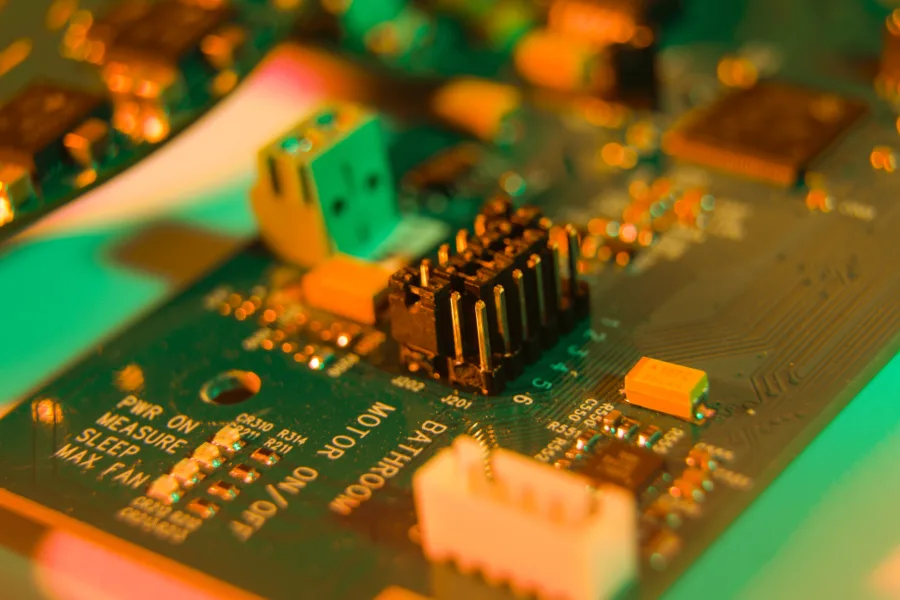

World-Class Engineering Excellence

Excellence in engineering is the cornerstone of any successful medical device. We make use of methodologies, tools, and technologies used to ensure that the highest standards of engineering are met. Embracing cutting-edge techniques results in innovative, effective, and competitive solutions.

High-Quality Assurance and Testing

The safety and performance of medical devices are paramount for us. High-quality assurance and testing are integral to ensuring the reliability of these products. Our approach ensures quality control measures, testing protocols, and validation procedures that guarantee that the end product meets the highest quality standards and is compliant with industry regulations.

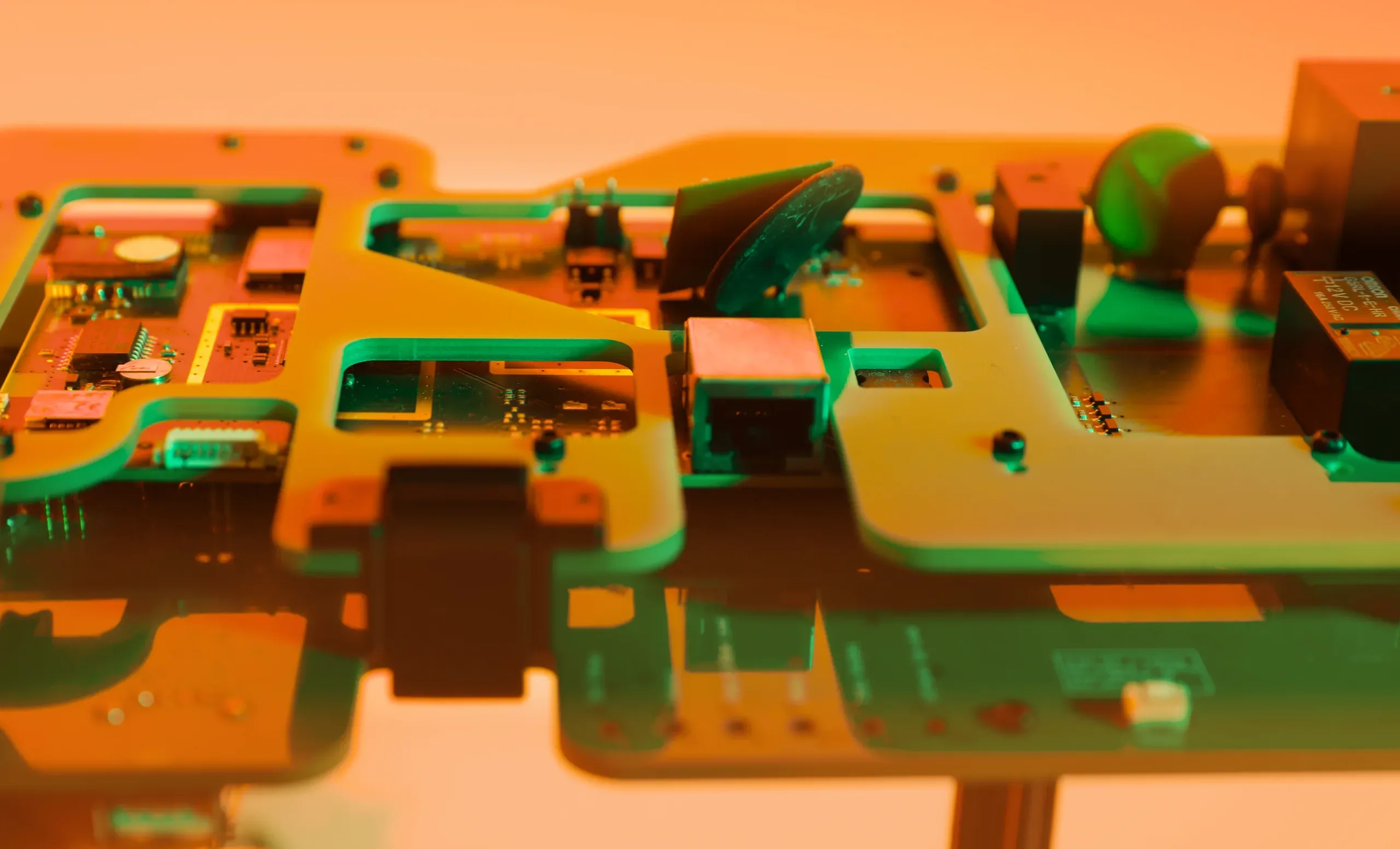

In-House Manufacturing Capabilities

Our in-house manufacturing capabilities are a game-changer in medical device development. Manufacturing the concepts we have developed ourselves, provides flexibility, scalability, and adherence to stringent quality standards. By controlling the entire manufacturing process, we can ensure faster turnaround times and maintain consistent product quality.

Ensuring Regulatory Compliance

Navigating the complex world of regulatory approvals and certifications is a formidable challenge in medical device development. We are a product development partner that understands the intricacies of obtaining regulatory approvals and ISO certifications. Compliance is not just a legal requirement but a mark of product safety and quality.

Work with us to bring your innovation faster to the market

In summary, our end-to-end medical device product development and engineering services are invaluable for our partners and innovators in the healthcare and medical device industry. The comprehensive support we offer across all stages of development simplifies the process and ensures a smooth transition from concept to market. Co-creation fosters collaboration and innovation, while our world-class engineering excellence guarantees that products meet the highest standards. High-quality assurance and testing are essential for product reliability and regulatory compliance. In-house manufacturing capabilities offer control and quality assurance, while navigating the regulatory landscape requires expertise and experience.

We offer a partnership that provides these services as a turn-key solution for our customers, a genuinely valuable asset in the journey towards delivering innovative and life-changing medical devices to the world.

Accelerate your product development journey and partner with us to bring your innovative ideas to life.

Contact Turkka Laakkio Partner Dream Devices for more information.