Manufacturing Optimization and Production

From Design to Scalable Production

We optimize manufacturability already during the design phase.

Agile Manufacturing Process

We provide comprehensive production optimization and manufacturing services, ensuring a smooth transition from design to production and commercialization.

Key focus areas

- Quality assurance

- Production cost efficiency

- Lifecycle cost management

- Timely market launch

Pilot Series and Scalable Production

Pilot series allow product demonstration, testing, and delivery before mass production. This enables early marketing and validation through user testing before full-scale manufacturing.

For low-volume production, we use mass production methods adapted to smaller batch sizes, reducing risks and optimizing costs.

Contract Manufacturing

We provide manufacturing services, including assembly, testing, and delivery of devices. Our production capacity scales to your needs, ensuring that your product meets quality requirements. Our flexible approach enables efficient production, even for smaller batches, without compromising quality.

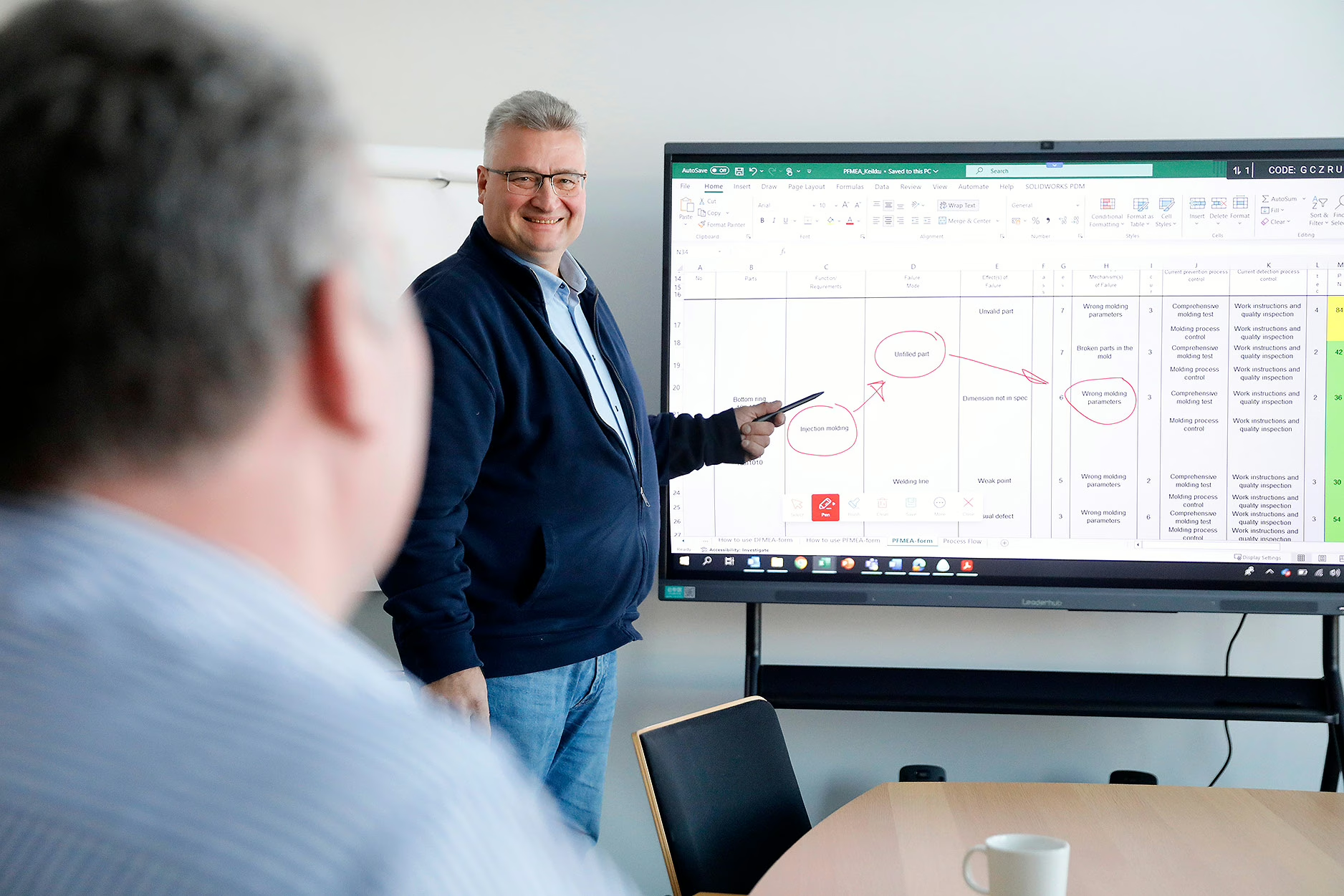

Agile Manufacturing Process

We provide comprehensive production optimization and manufacturing services, ensuring a smooth transition from design to production and commercialization.

Key focus areas

- Quality assurance

- Production cost efficiency

- Lifecycle cost management

- Timely market launch

Pilot Series and Scalable Production

Pilot series allow product demonstration, testing, and delivery before mass production. This enables early marketing and validation through user testing before full-scale manufacturing.

For low-volume production, we use mass production methods adapted to smaller batch sizes, reducing risks and optimizing costs.

Contract Manufacturing

We provide manufacturing services, including assembly, testing, and delivery of devices. Our production capacity scales to your needs, ensuring that your product meets quality requirements. Our flexible approach enables efficient production, even for smaller batches, without compromising quality.

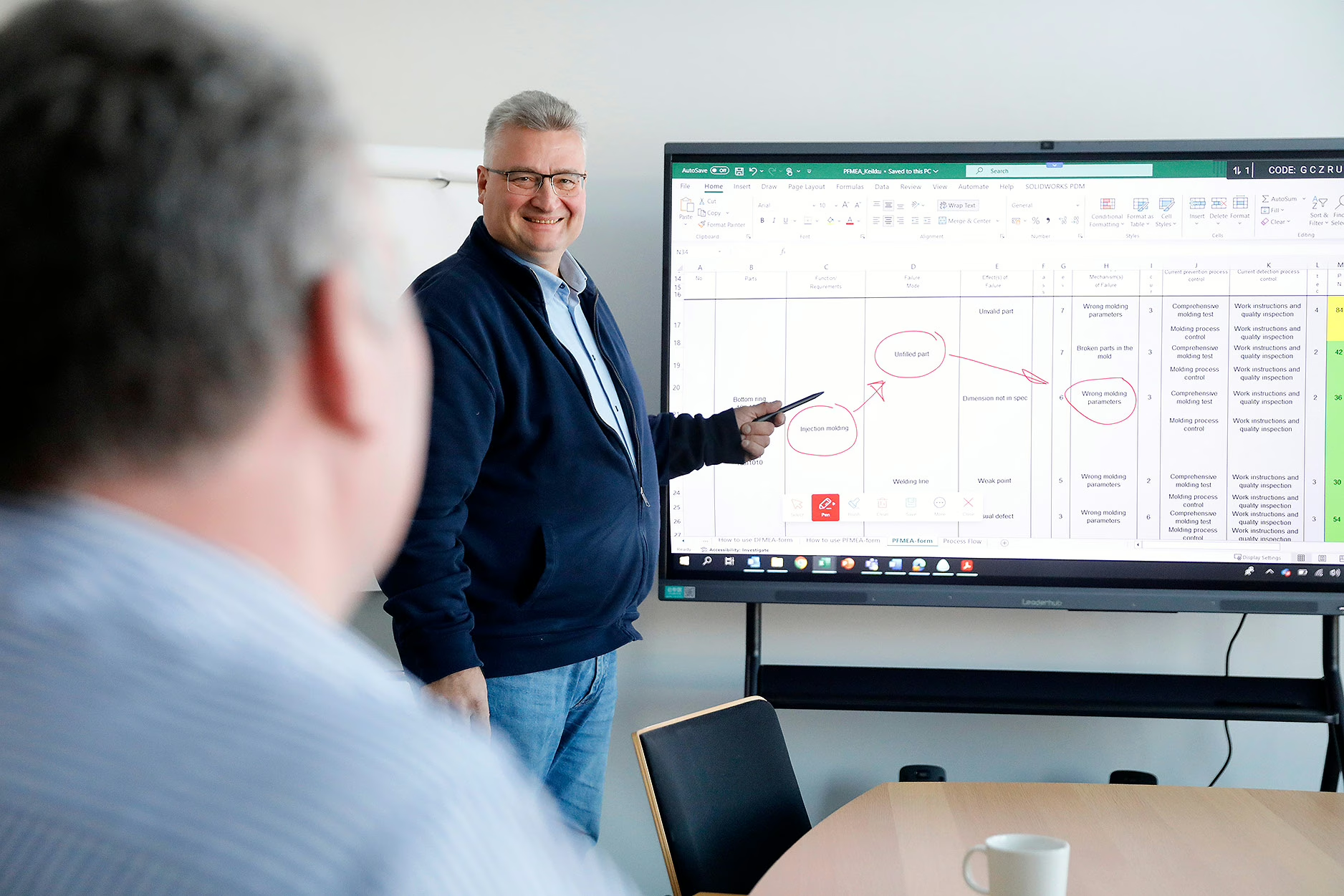

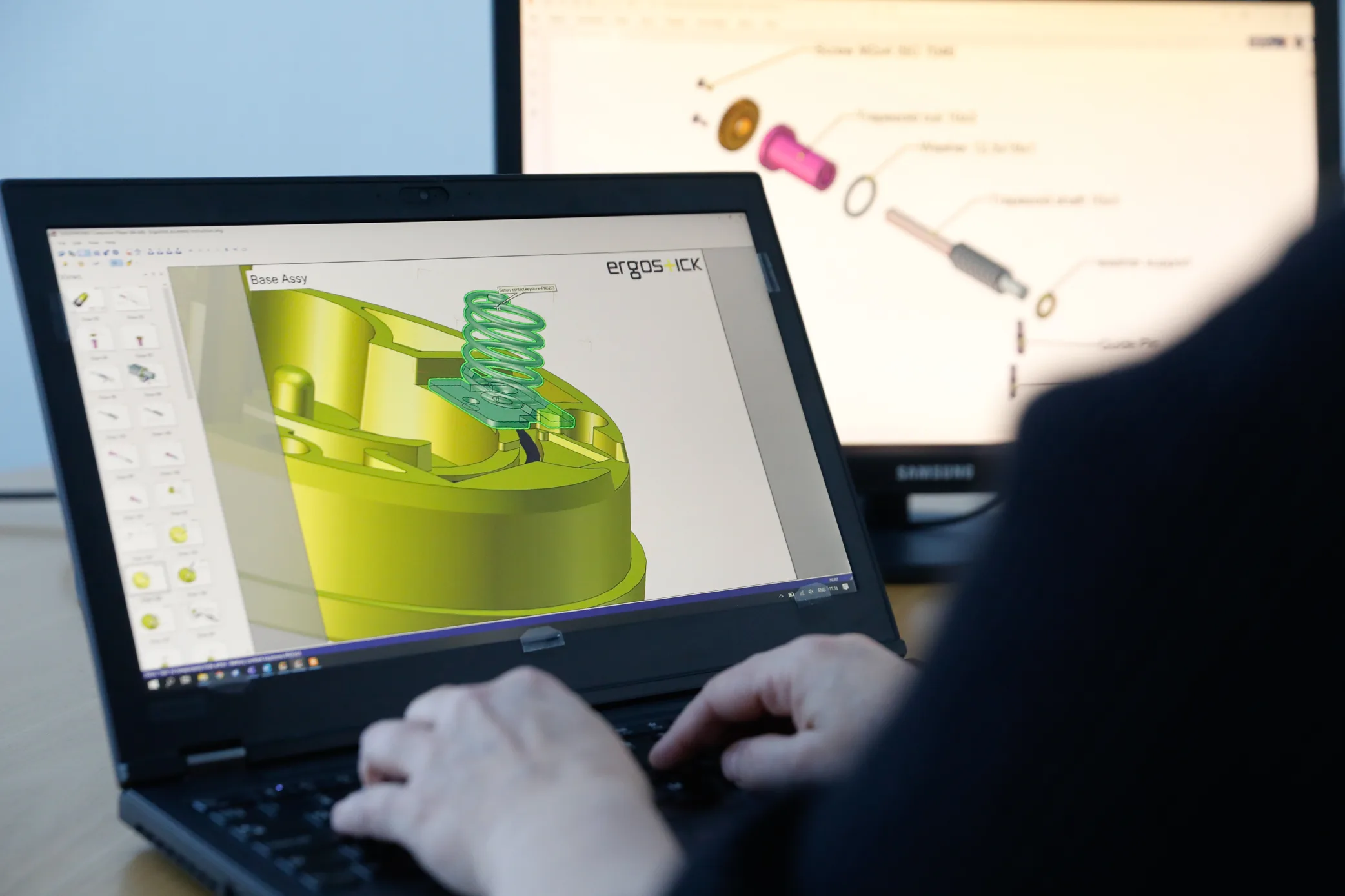

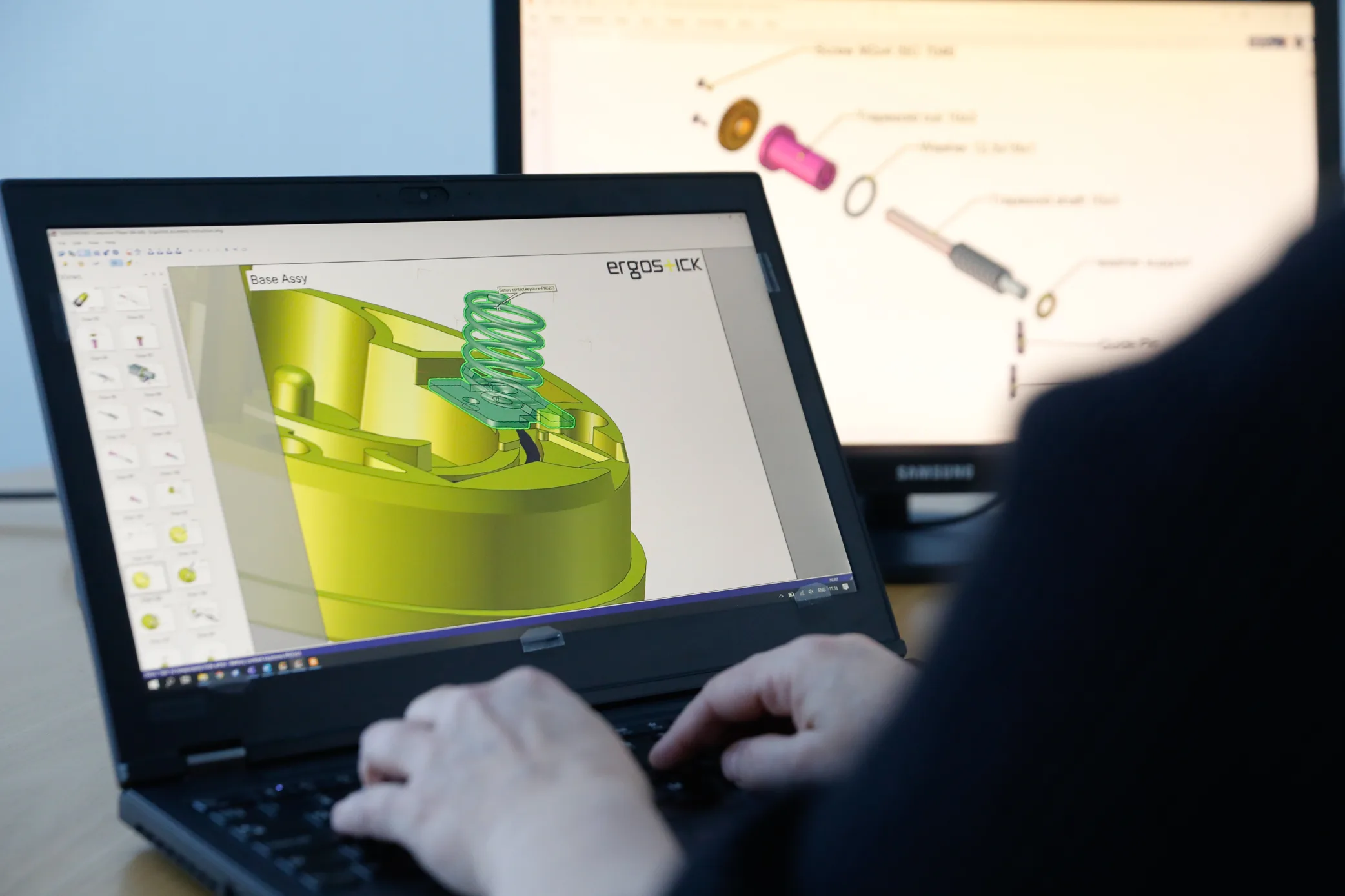

Injection Molding and Assembly

Our in-house injection molding machines enable an agile product development process and seamless transition to production. Our advanced model enhances component manufacturing efficiency and cost-effectiveness while providing valuable data for further development, reducing late-stage development costs.

We also offer raw material testing and trial runs to accelerate optimization and ensure product quality during development.

Mold and Component Supply

We supply molds and components based on our customers’ own designs, offering high-quality and cost-effective solutions with fast delivery times. Our extensive expertise enables us to select the optimal manufacturing method for each specific need.

Our expertise spans various production technologies

- Injection molding

- Metal casting

- Reaction Injection Molding (RIM, PUR)

- Extrusion

- Vacuum and thermoforming

- CNC machining and welding assembly

Dream Devices is a forerunner in many ways. They operate at the center of digitalization, helping their customers to bring intelligence to their products, services and devices.

Anna-Mari Lahtinen

Health and Wellbeing Professional, Hyvää Elämää Services

Related Articles